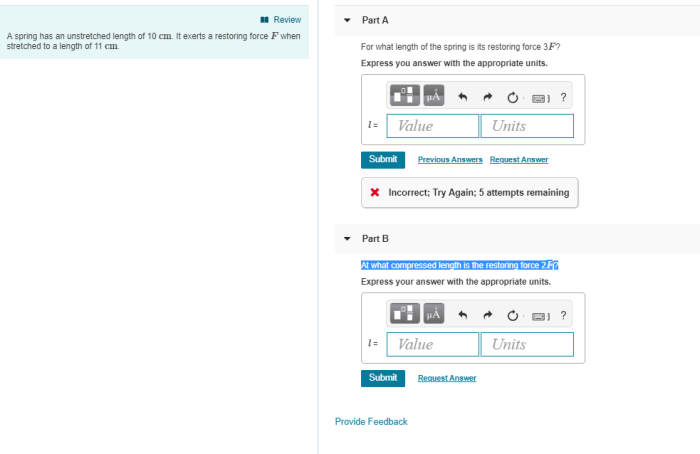

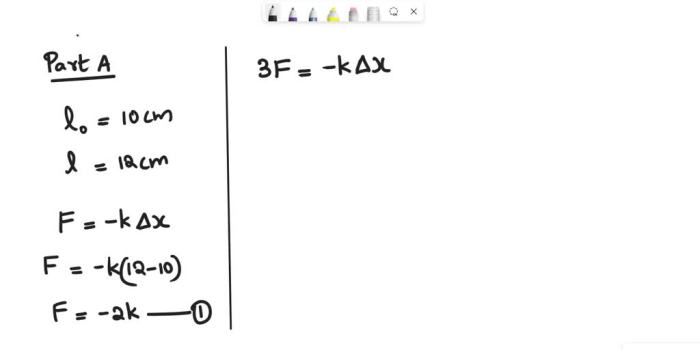

A spring has an unstretched length of 10 cm, making it a crucial parameter in understanding spring behavior and design. This guide delves into the significance of unstretched length, exploring measurement techniques, influencing factors, and practical applications.

The unstretched length of a spring refers to its natural length when it is not subjected to any external forces. It serves as a reference point for measuring spring deformation and calculating spring constants. Accurately determining the unstretched length is essential for predicting spring performance and ensuring optimal functionality.

Unstretched Length: A Spring Has An Unstretched Length Of 10 Cm

An unstretched length of a spring refers to the length of the spring when it is not subjected to any external force or deformation. It represents the natural length of the spring in its relaxed state.

The unstretched length is a crucial parameter in understanding the behavior of a spring. It serves as a reference point for measuring the spring’s displacement and calculating its spring constant.

Measurement of Unstretched Length

Measuring the unstretched length of a spring involves the following steps:

- Suspending the spring vertically from a fixed point.

- Attaching a small weight to the bottom of the spring.

- Measuring the distance between the fixed point and the bottom of the weight.

Factors Affecting Unstretched Length, A spring has an unstretched length of 10 cm

Several factors can affect the unstretched length of a spring, including:

- Material:The material used to make the spring influences its stiffness and, consequently, its unstretched length.

- Wire Diameter:Springs with thicker wire diameters have a shorter unstretched length.

- Number of Coils:Springs with a greater number of coils have a longer unstretched length.

Applications of Unstretched Length

The unstretched length of a spring finds practical applications in various fields, such as:

- Spring Design:Engineers use the unstretched length to design springs with specific stiffness and performance characteristics.

- Vibration Isolation:Springs with carefully calculated unstretched lengths can effectively isolate vibrations and prevent damage to sensitive equipment.

Comparison of Springs

Different types of springs exhibit varying unstretched lengths. For instance, compression springs have a shorter unstretched length compared to extension springs.

Understanding the unstretched lengths of different spring types is essential for selecting the most suitable spring for a particular application.

FAQ Guide

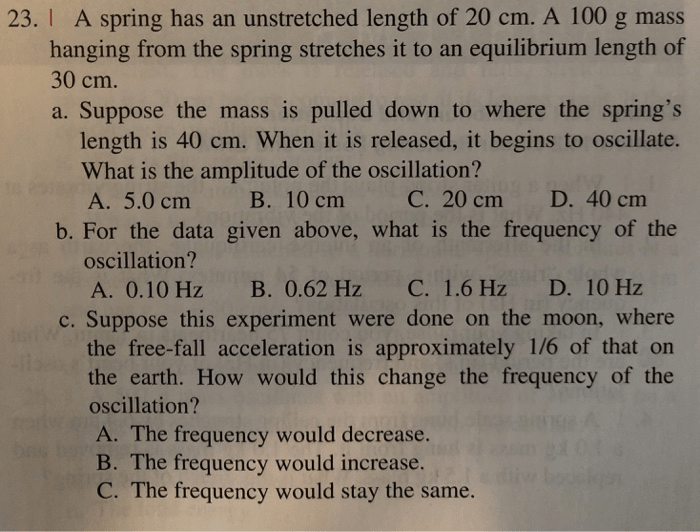

What is the significance of unstretched length in spring design?

Unstretched length is crucial for determining spring stiffness, resonant frequency, and maximum deflection. It influences the spring’s ability to store and release energy, making it a critical parameter in designing springs for specific applications.

How can I accurately measure the unstretched length of a spring?

To measure the unstretched length, suspend the spring vertically and attach a small weight to its end. Gradually remove the weight while observing the spring’s extension. The point at which the spring returns to its original length is its unstretched length.

What factors can affect the unstretched length of a spring?

Factors such as material properties, wire diameter, and manufacturing processes can influence the unstretched length of a spring. Changes in these factors can alter the spring’s stiffness and overall performance.